- Easy Installation and Maintenance: The design of modern pump units takes ease of installation and maintenance into consideration. They typically feature standard interfaces and structures, reducing installation time and labor intensity. Regular maintenance is simple, lowering the operational costs of the equipment.

|

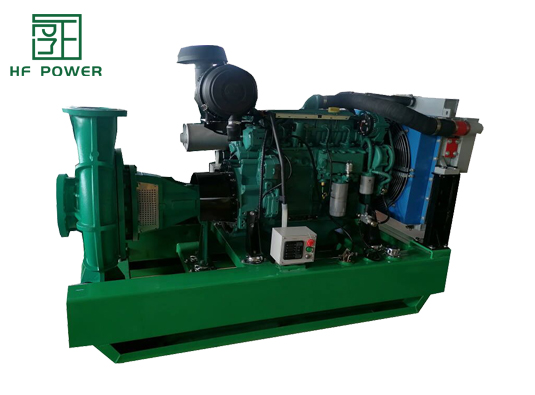

diesel water pump sets specification

|

||||||||

|

Pump details

|

||||||||

|

Pump flow rate

|

400m3/h

|

|||||||

|

Pump head

|

60m

|

|||||||

|

Inlet and outet flanges

|

200mm*200mm

|

|||||||

|

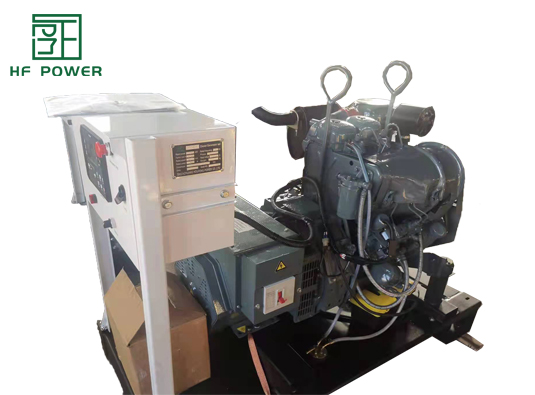

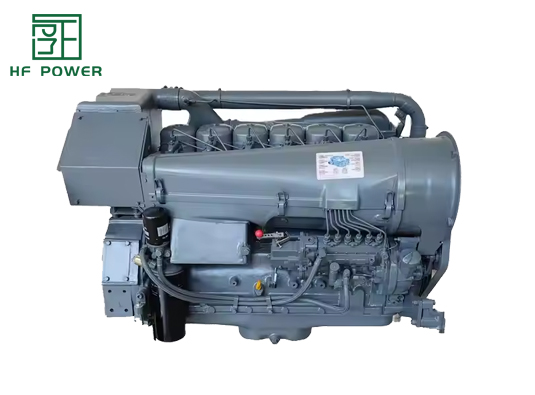

Engine details

|

||||||||

|

Brand

|

Deutz

|

|||||||

|

Model

|

BF4M1013(92kw/1500rpm)

|

|||||||

|

Type

|

in-line, 4-cylinder, 4cycle diesel engine

|

|||||||

|

Cooling way

|

Water cooled

|

|||||||

|

Aspiration

|

turbocharged

|

|||||||

|

Direction of rotation

|

counterclockwise(face to flywheel end)

|

|||||||

1. High Efficiency and Energy Saving

Pump units adopt advanced technology and design to achieve efficient fluid transportation and reduce energy consumption. Many modern pump units are also equipped with frequency converters, allowing the pump’s speed to be adjusted according to needs, which helps avoid energy waste.

2. Stable and Reliable

Pump units are usually subject to strict quality control and testing to ensure long-term stable operation. High-quality materials and precise manufacturing processes significantly extend the service life of the pump unit, reducing failure rates and maintenance costs.

3. Automated Control

Many pump units are equipped with automated control systems that can monitor the pump’s operating status, trigger alarms, or adjust operating parameters when needed. This ensures the pump operates at optimal conditions, effectively preventing damage caused by human error.

4. Versatile Applications

Pump units are not only used for water supply and drainage but also for cooling, pressurization, firefighting, and other functions, making them highly versatile. For example, in construction projects, pump units are commonly used in water supply and firefighting systems.

Application scenario