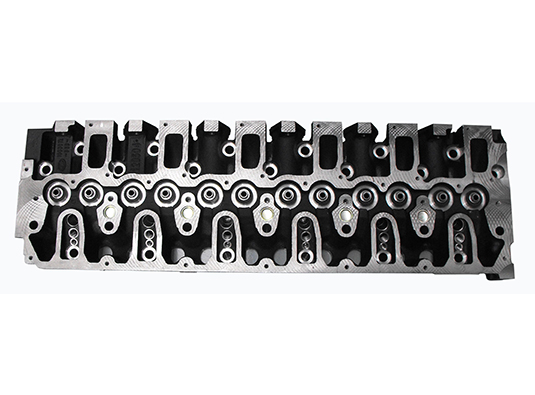

The cylinder head is the main component of the air distribution mechanism, and is an important component to make sure the intake and exhaust of combustion chamber air.

Material: The cylinder head is made of aluminum-magnesium alloy.

The highest temperature area of the cylinder head is in the “nose bridge area” between the intake and exhaust valves. When the cylinder head is working, the “nose bridge area” will suffer squeeze and stretch due to metal thermal expansion and contraction, and the cylinder head will crack under repeated action for a long time .

Our cylinder head is cast with anti-crack plate in the nose bridge area, and the thermal shock test equipment was used to test the anti-crack structure of the cylinder head “nose bridge area” to ensure the stability and effect of the structure.

Precautions: The cooling fin of the cylinder head should be kept clean. When cleaning the cooling fin, dust and debris should be blown out in the opposite direction of the cooling air flow.

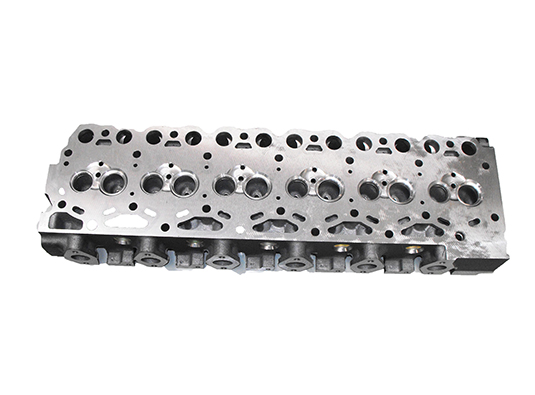

The cylinder head is the main component of the air distribution mechanism, and is an important component to make sure the intake and exhaust of combustion chamber air.

Material: The cylinder head is made of aluminum-magnesium alloy.

The highest temperature area of the cylinder head is in the “nose bridge area” between the intake and exhaust valves. When the cylinder head is working, the “nose bridge area” will suffer squeeze and stretch due to metal thermal expansion and contraction, and the cylinder head will crack under repeated action for a long time .

Our cylinder head is cast with anti-crack plate in the nose bridge area, and the thermal shock test equipment was used to test the anti-crack structure of the cylinder head “nose bridge area” to ensure the stability and effect of the structure.

Precautions: The cooling fin of the cylinder head should be kept clean. When cleaning the cooling fin, dust and debris should be blown out in the opposite direction of the cooling air flow.