At the same time measuring a-a, b-b roundness in both directions, not more than 0.05mm. To the ends of the main journal as a benchmark, measuring the radial runout of the journal, should be less than 0.1mm. Check the axial movement of the crankshaft, should not exceed 0.4mm. To F6L912 and 913, for example, the axial movement of the crankshaft is 0.15-0.314, after the overhaul to ensure that this requirement (thrust main bearing cover width, in the standard preload F = 270N.M detection of tile Roundness, should not exceed 0.05mm.) 3.2 Check the cylinder head carefully check the cylinder head with or without cracks. Detection of the amount of valve cover down, the limit size of 5.8mm, over the General Assembly affect the compression ratio. Detection of valve seat and valve sealing situation, generally see the valve print width between 0.3-0.5mm and to be correct, uniform. The valve seat is in the seat of the cylinder head is the interference assembly, the interference is 0.115-0.160. Installation and removal is often heated to 220 ℃, Deutz company specifically for the user with a special drill and tools. 3.3 cylinder liner and piston ring detection cylinder liner and piston ring detection position shown in Figure 2, measured 1,2,3,4 position a-a, b-b in two directions to do a good job. Cylinder linen wear serious when the first air ring to reach the highest position of the cylinder, the fingernail can be clearly felt the steps. The limit value should be 0.2mm, this time the cylinder honing pattern is no longer exist. Currently widely used is the replacement of the standard cylinder liner, this time to replace the standard piston and piston ring for assembly. 3.4 Detection of the intake and exhaust valve between the valve and the intake valve between the valve and the valve with the gap limit of about 0.3-0.5mm, beyond this limit should replace the new valve or valve. Valve ducts to use the increase, as shown in the table below (to F6L912,913 as an example). All valves and valves should be replaced at the same time. Check valve spring for corrosion, cracks. And measure its free length. F6L912,913 engine valve duct size

- Home

-

Products

- Deutz Technology Diesel Engine

- B/FL912/913 B/FL914 D914 B/FL413/513 BFM1013/2012 TCD2012 TCD2013 BFM1015 TCD2015 TD226/WP FL511

- Cummins Technology Diesel Engine

- 4BTA3.9 6BTA5.9 6BTAA5.9 6LTAA8.9 QSB 3.9 QSB 5.9 QSB6.7 QSC8.3 QSL8.9

- Marine Diesel Engine

- Weichai Marine Diesel Engine Cummins Marine Diesel Engine HF Power Marine Diesel Engine

- Diesel Generator Set

- Deutz Generator Set Cummins Generator Set Perkins Generator Set Lovol Generator Set Ricardo Generator Set

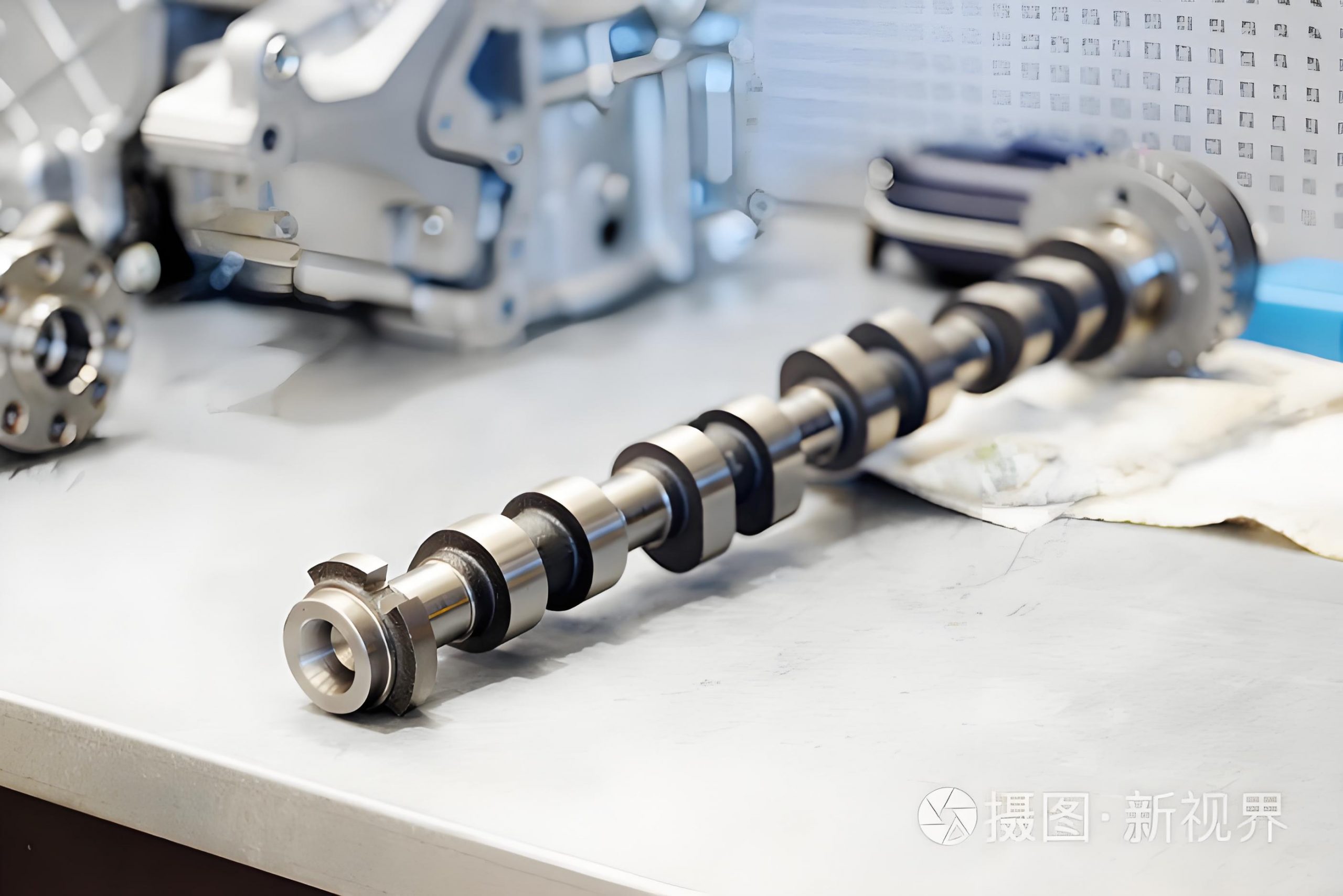

- Diesel Engine Spare Parts

- Cylinder block Cylinder head Connecting rod Crankshaft Flywheel Flywheel Housing Flywheel Gea ring Cylinder liner kit Cylinder Liner Piston Piston Ring Camshaft Intake valve &Exhaust valve Valve Tappet Rocker Arm Fuel injection pump Fuel Injector Oil filter&Fuel filter&Air filter Gear System Starter Oil cooler Alternator Hydraulic Oil Pump Cooling Fan Water pump Overhauling repair kit Turbocharger

Our Products: Diesel engines: DEUTZ, widely used for vehicle, industrial, power generation,marine, agricultural machinery; Generator sets: DEUTZ, CUMMINS, PERKINS, LOVOL, RICARDO series Diesel Generator Sets and WATER PUMP SET; ENGINE SPARE PARTS: DEUTZ, CUMMINS, PERKINS, LOVOL, BENZ, CAT, MTU, MAN etc.

view more - Case

- News

- Service

- About us

- Contact us

Email

admin@galloppower.com